Retina A.I. Deep Learning Vision Suite

Retina Deep Learning Software Built from Scratch out of the Watch Manufacture Valley.

Automating visual inspection helps manufacturers to improve productivity, quality and profitability. The embedded solutions allows having control and visibility over your production machines in Realtime 24/7 on the edge on the machine without the need to transfer any data to the web.

The Deep neuronal network helps solving challenging vision applications within minutes instead of requiring an expert finetuning during weeks and modifying parameters frequently during production shifts. The cutting edge visual inspection algorithms of Retina will solve quality issues by catching challenging defects and enhance products quality quickly.

Retina A.I. Vision helps absorbing natural variations & deviations of good products but handles easily variation of defects as well. The robustness and consistency of our algorithm is a powerful tool to decide quickly the conformity of the products along the day.

Our Retina deep learning software helps identifying defective products in real-time 24/7 with the same accuracy and flexibility of a human. But without being influenced by fatigue and moods.

Only deep learning can inspect several parts per second precisely, reliably and constantly.

With Retina deep learning software, there is no need to be a Data scientist, Deep learning expert nor a Computer vision engineer to be able to deploy quickly an A.I. vision inspection solution.

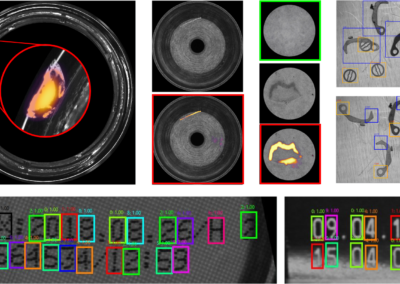

Most of the challenging applications will be covered with the 4 flavors described below.

In term of integration, Retina can be used in Standalone or added as a library / plugins (.NET dll, C/C++ dll) for most vision environement (including Labview, Visual Studio and OpenCV).

“3HLE” is not only a software licensing company, we are used to deliver entire hardware (industrial IPCs & cameras) & software solutions to our customers.

We are vision experts working on vision applications on a daily basis. Therefore we are designing and writing software with real applications/constraint in our mind. In the same philosophy, we strive to deliver the simplest and the most intuitive solutions for vision engineers/developpers with a “minimum parameters and clicks” possible.

The complex and high speed visual quality inspections are based on embedded “Artificial Intelligence” deep learning server/solutions. Images are processed directly on the edge of the machines. Our solutions are deployed and processed in realtime on a local IPC with GPU on the machine or within the factory network. Manufacturers will be able to access production datas and images on the edge of their machines or through their internal network without a any internet connection.

“3HLE” is mainly offering Turn-Key solutions including Hardware, Integration of Software and Automation Processes dedicated to high speed automated Computer Vision Quality Control applications.

For more Showcases, check out our Sucess Stories pages or check out our Products pages to learn more about our hardware and software solutions. We are working to build up more and more contents in those sections, please subscribe to our “3HLE” LinkedIn, FaceBook or Youtube chanels to get notified as soon as new contents will be available.

1. Flavor Cherry:

-

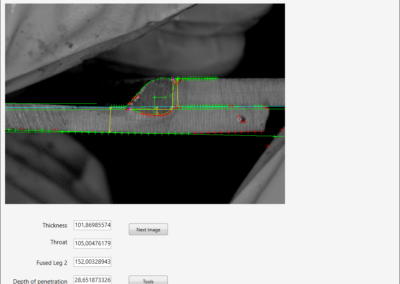

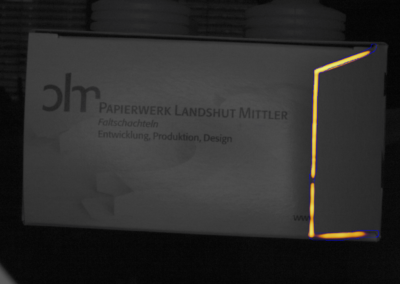

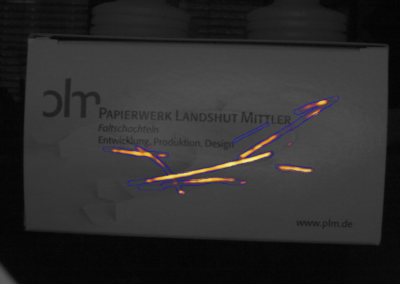

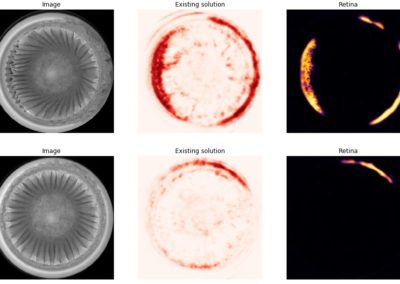

- Aesthetic anomalies detector enables detection of challenging/complex or shiny surfaces down to 1-pixel accuracy. This void the need of chaining several tools with several features sizes.

- Recipe/model change during runtime is done via a simple number input. This voids the need of complex scripting.

- (Advanced) Multi class defects detection voids chaining several different types tools for detecting then classifying defects.

- Runtime parallel multi-instance/threads execution on a single GPU. This allows reducing hardware cost and maintenance cost.

- Optimized Graphic/CUDA RAM memory allocation and usage.

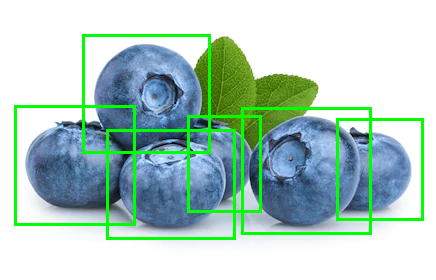

2. Flavor Blueberry:

-

- Used to locate parts with huge variation/flexibility or a wide family of similar objects.

- Runtime parallel multi-instance/threads execution on a single GPU. This allows reducing hardware cost and maintenance cost.

- Optimized Graphic/CUDA RAM memory allocation and usage.

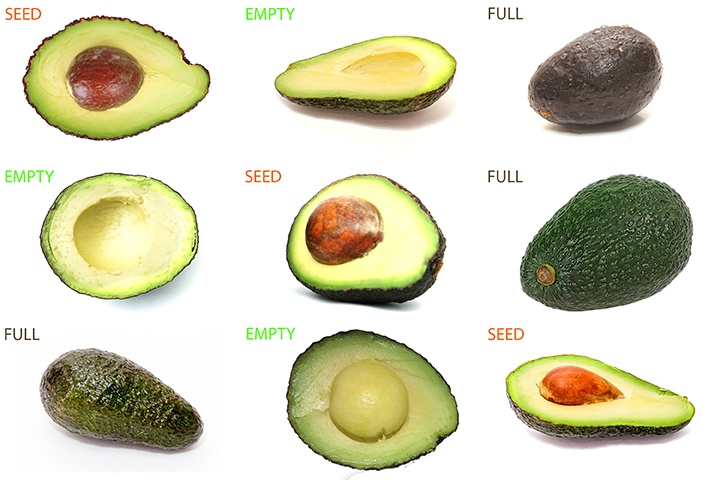

3. Flavor Avocado:

-

- Used to classify objects in an image.

- Runtime parallel multi-instance/threads execution on a single GPU. This allows reducing hardware cost and maintenance cost.

- Optimized Graphic/CUDA RAM memory allocation and usage.

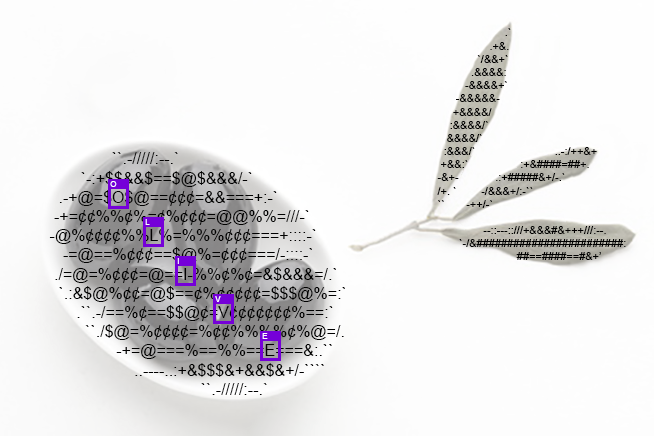

4. Flavor Olive:

-

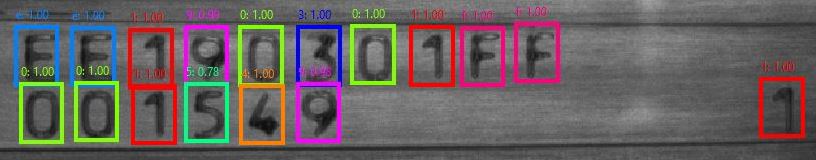

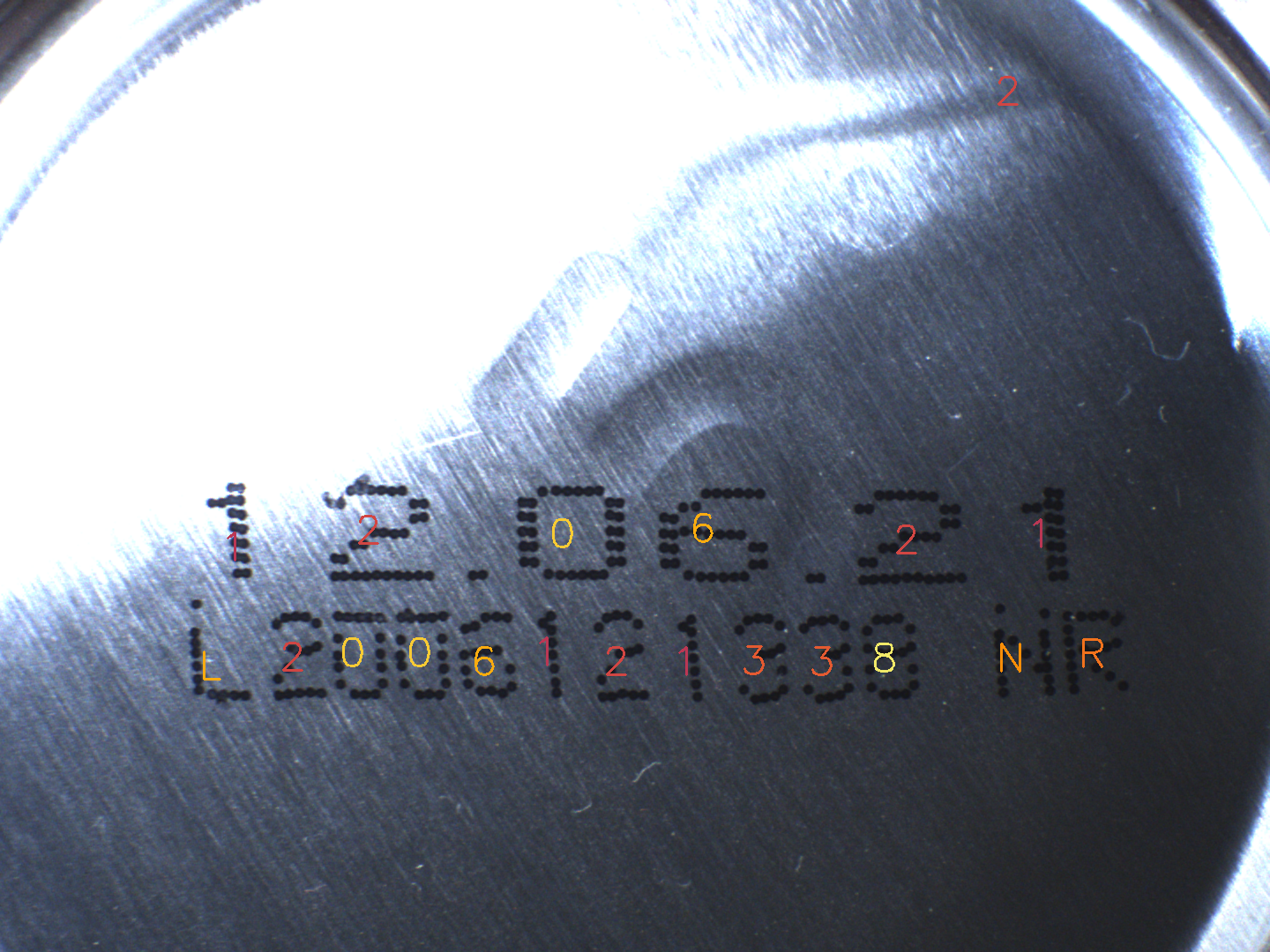

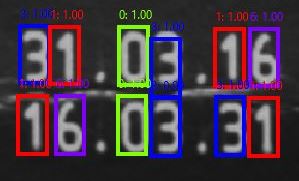

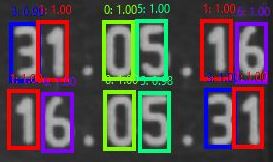

- Olive is an OCR tool used to read DPM, laser & dot-injet characters with noisy background surfaces.

Please fill in the section below to receive the selected PDF Datasheet by email or subscribe to our newsletter to get the most up-to-date contents

Applications and Showcases

RETINA-CHERRY

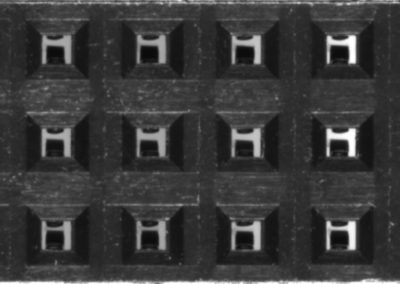

Food & Beverage snack packaging sealing inspection

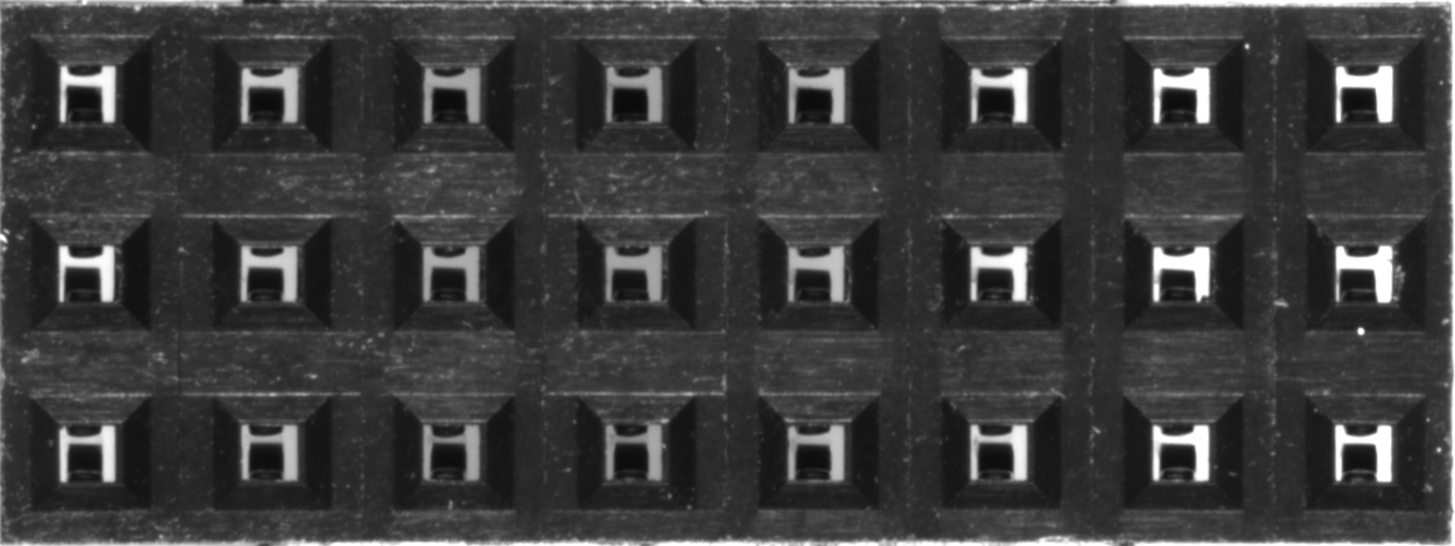

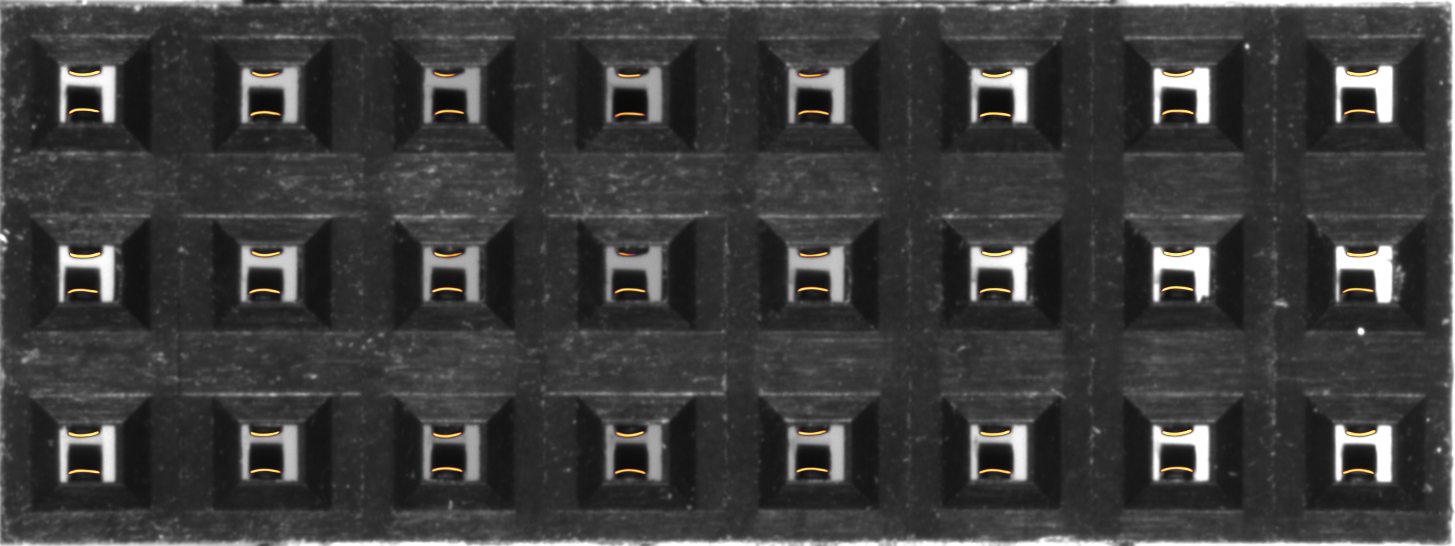

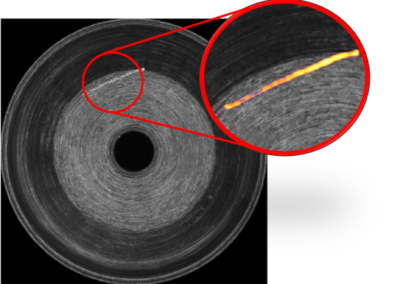

Barely visible metal beams detection for metrology on high end connectors (gap distance measurement)

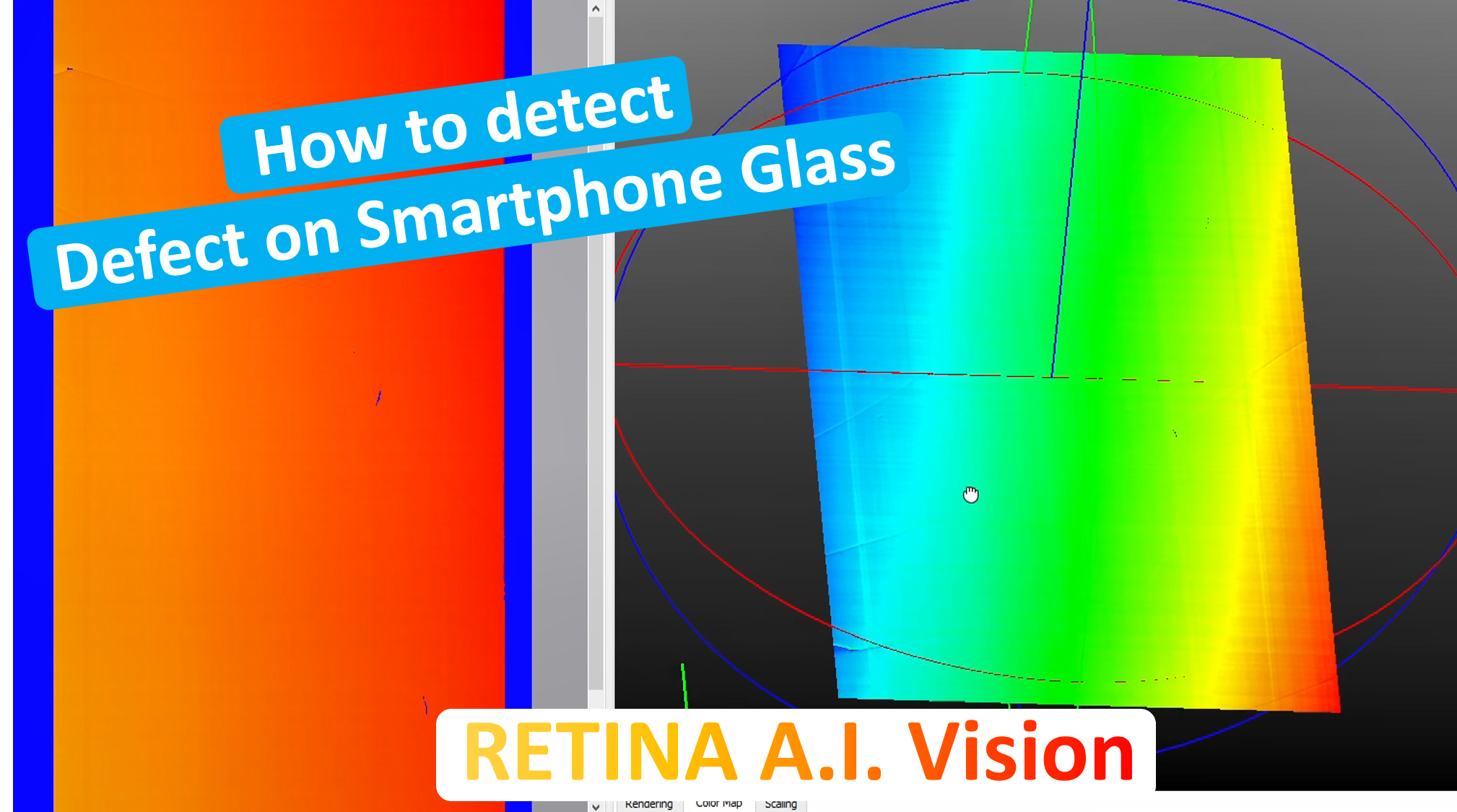

Smartphone displays /glass defect detection

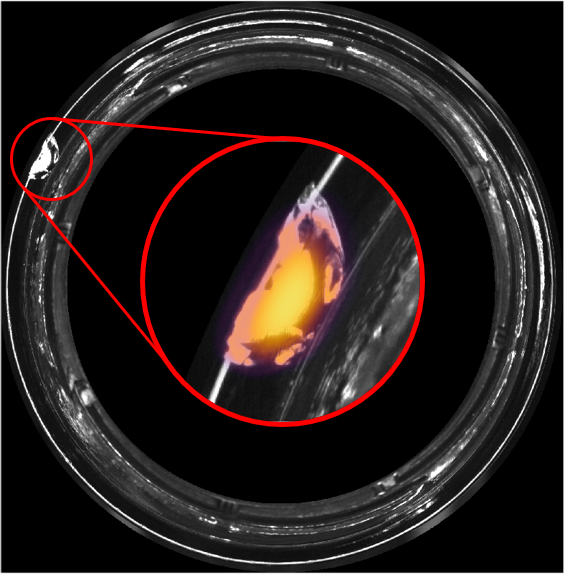

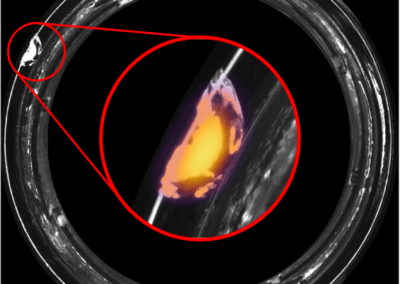

Defects detection on Glass Jar Inspection:

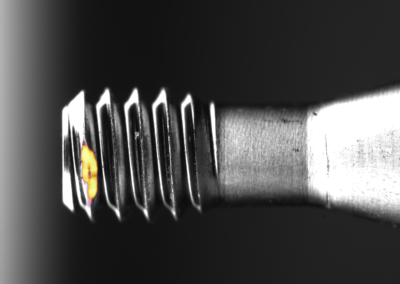

Quality inspection on Medical/surgical screw:

RETINA-OLIVE OCR

Realtime OCR reading on PET bottles at 40k units/hour

Reading text (OCR) on metalic, noisy and uneven surfaces:

Youtube Showcases

Luxury watches manipulation and quality control:

Video showing the simple workflow for integrating Retina-OCR in Visual Studio:

Video showing Retina-Cherry inspecting scratches on transparent glass and shiny metallic parts:

Youtube video showing the simple workflow for integrating Retina-Cherry in Visual Studio:

Youtube video demo showing a RETINA-OLIVE Deep Learning reading succesfully OCR on the bottom of Aluminum Can:

Youtube video demo showing a RETINA-OLIVE Deep Learning reading easily OCR on the bottom of Aluminum Can:

Youtube video demo showing a Deep Learning showing a demo of a packaging quality inspection:

Youtube video showing a Deep learning industrial coffee production line quality inspection:

How to detect scratches on glass and shiny metallic parts

Detection of scratches on glass and shiny watch parts

Retina heatmap on connector beam for gap distance measurement

Connector beam detection for gap distance measurement

Comments are Closed