Services for Automated Visual Quality Inspection and Robot Guidance

Solutions & Services in our Area of Expertise

FEASIBILITY & PROOF of CONCEPT

Whether it is Vision or Robotics applications, we usually start with a feasibility & evaluation phase. Based on real products or its images, we can clear doubts, refine specifications and define a realistic budget for the final application.

Adding this extra step can result in a higher return on investment and less time and money wasted on trial and error.

Feasibility studies can be especially helpful to understand and set realistic expectations. It is vital to invest in one early on to maximize the benefits of automation and quality control.

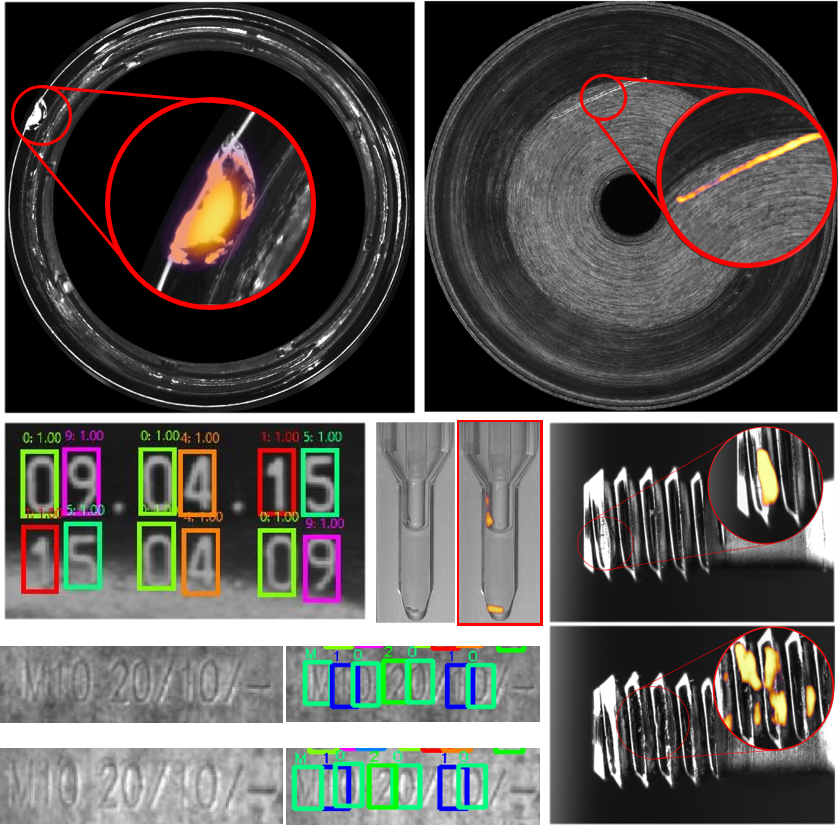

AUTOMATED A.I. VISION SOLUTIONS

Our Retina A.I. assisted Vision Quality Control is completing our reliable pick & place and bin picking solutions. We usually deliver turnkey solutions (hardware & software) to end users as well as machine builders integrating into their production machines wihtout the need to have a team of vision engineers.

With our Intuitive Vision Solution, there is no need to be a Data scientist, a Deep learning expert or a Computer vision engineer to be able to deploy quickly & reliably an A.I. vision solution.

Our Deep Learning-based image analysis enables happy manufacturers and satisfied end users to automate their production with the most advanced visual quality inspection algorithm for catching challenging defects very quickly.

SMART ROBOT CONTROL & VISUAL GUIDANCE

Our smart vision-guided robots are more versatile and adaptable than traditional robots (programmed to perform specific tasks in a controlled environment). Our vision-guided robots are designed to perform a wide range of tasks in dynamic and unpredictable environments. For example after a tool change or a new parts/references change, our solution will auto-calibrate itself and correct offset in order to:

- Increased productivity: the machine will be able to be up and running quickly freeing up workers to focus on more complex tasks.

- Reduced costs: the automatic detection of references and positions change will improve efficiency as there is ne need to refine vision & robot over and over again.

- Increased safety: as there is no need of human intervention, it lowers the risk of collision and damge due to human interaction.