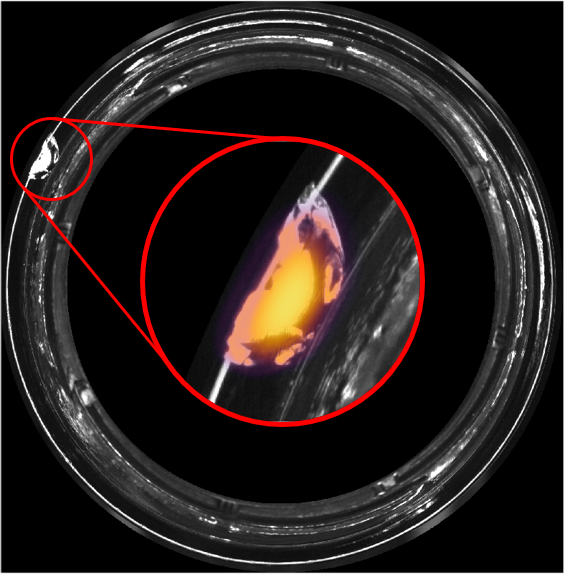

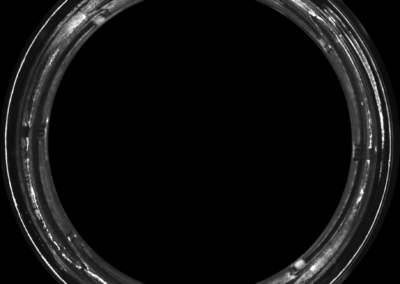

How to Easily Detect Glass Cracks for Food and Beverage in Factories using A.I.

Highly Efficient “Deep Learning Retina-Cherry” Training and Inference Solutions

The RETINA deep learning visual inspector is the most accurate for detecting cracks/anomalies on shiny and transparent parts such as glass jars and bottles. It can control the quality of the parts as if a human was doing the job but at a much higher speed and never fail due to fatigue.

There are many high cost and complex conventional vision (rules-based systems) inspection systems on the market that are already operating on production lines since years. They perform quite well, but due to the reflective and transparent nature of the glasses, it is quite difficult to rules-based correctly vision system to detect those defects accurately. Therfore, to avoid allowing bad products arriving in the hand of the end customers, those systems must be set to over-reject. Therefore, there is a few percentage of false positive rate (over reject). This will cost a fortune to manufacturers that are running high volume of parts.

Therefore, our Retina deep learning based inspection system is the most appropriate for such complexes applications. Because with Retina deep learning software, there is no need to to write a single line of code nor masterize computer vision to be able to deploy quickly an A.I. vision inspection solution.

Feel free to challenge Retina Cherry Defect Detection Deep Learning algorithm with your application! We are ourselve surprised by its performance on very low resolution images and high noise backgrounds!!! Contact us for a demo on your samples, we will be glad helping you chosing the most appropriate camera setup and software solution. For more Showcases, check out our Success Stories page or check out our Products pages to learn more about our solutions.

“3HLE” is offering Turn-Key solutions including Hardware and integration of Software dedicated to high speed automated quality control applications. If you are concerned of “Constant quality” and would like to reduce final product waste by detecting defects at an earlier stage of the production, feel free to drop us an email or a phone call to discuss about improving or retrofitting your production lines to increase throughput and customer complaints using cutting edge technologies.

Please fill in the section below to receive the selected PDF Datasheet by email

Comments are Closed