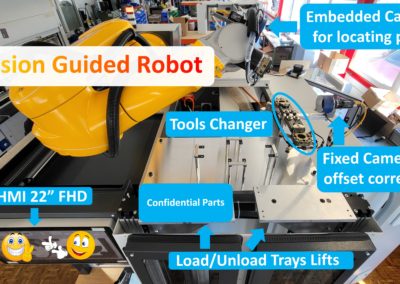

Vision Guided Robots with Visual Quality Inspection using Cutting Edge Technologies

Revolutionize Your Manufacturing Process with Advanced Automation

Ensure Perfect Quality & Throughput, Every Time

Harness the power of cutting-edge technology with our Vision-Guided Robot for Pick & Place alongside Visual Quality Control. Designed to streamline your manufacturing operations, this integrated solution combines precise robotic automation with rigorous quality inspection, ensuring unparalleled efficiency and product integrity.

Vision-Guided Pick & Place:

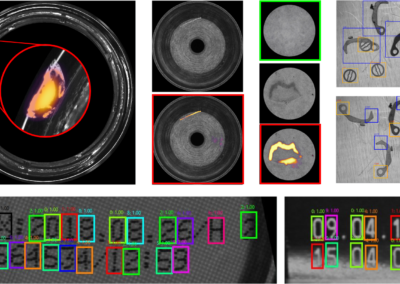

- High-Precision Cameras: Our system employs high-resolution cameras to accurately locate and identify objects within the workspace, regardless of their orientation.

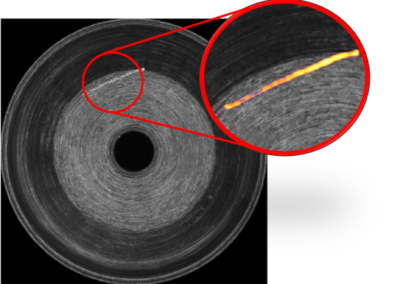

- Advanced Algorithms: Machine learning and computer vision algorithms enable the robot to dynamically adapt to varying shapes, sizes, and positions of items.

- Seamless Operation: The robot’s movements are synchronized with real-time visual data, ensuring accurate and efficient pick and place operations.

Visual Quality Control:

Automated Inspection Systems

- Defect Detection: Integrated cameras inspect each item for defects such as scratches, dents, or incorrect dimensions before and after placement.

- Color and Pattern Recognition: The system verifies correct colors and patterns to ensure each product meets your specific quality standards.

- Automated Sorting: Defective items are automatically sorted and separated from the production line, maintaining a high-quality output.

Benefits

- Increased Efficiency: Automate repetitive tasks to significantly boost productivity and reduce human error.

- Enhanced Quality Assurance: Ensure each product meets rigorous quality standards with comprehensive visual inspections.

- Cost Savings: Reduce waste and operational costs by catching defects early in the production process.

- Flexibility: Adapt to different products and production requirements with customizable settings and easy reprogramming.

Comprehensive Reporting

- Detailed Analytics: Generate in-depth reports on seal quality, defect trends, and overall packaging performance.

- Customizable Dashboards: Visualize data in a way that best suits your operational needs, aiding in quick decision-making.

Integration with Existing Systems

- Seamless Compatibility and Retro-fit: Easily integrate our quality control solutions with your current production line and packaging equipment.

- Scalable Solutions: From small-scale operations to large manufacturing plants, our systems can scale to meet your needs.

Benefits of Choosing 3HLE

- Reliability: Depend on a system designed for consistent accuracy and durability.

- Innovative Technology: Stay ahead with the latest advancements in packaging quality control.

- Support and Integration: Benefit from expert installation, training, and ongoing support, as well as seamless integration with your existing systems.

Transform Your Production Line Today

Elevate your manufacturing process with our Vision-Guided Robot for Pick & Place alongside Visual Quality Control. Contact us now to learn more about how this innovative solution can enhance your operational efficiency and product quality.

Embrace the future of manufacturing with our sophisticated automation solutions, ensuring precision, efficiency, and top-notch quality control in every product.

3HLE: Turn-Key Automation for High-Speed Vision Quality Control

At 3HLE, we specialize in providing turn-key automation solutions that integrate hardware, A.I. software, and advanced automation turn-key solutions—all designed for high-speed, automated computer vision quality control applications. Whether you’re looking to enhance efficiency or optimize precision, our solutions help businesses streamline operations with cutting-edge technology.

Explore our Success Stories to see our solutions in action, or visit our A.I. Robotics & Vision Solutions page to learn more about our industry-leading hardware and software offerings. We’re continuously expanding our content—subscribe to our LinkedIn, Facebook, or YouTube channels to stay updated with the latest insights and innovations.

Sustainable Solutions for a Greener Future

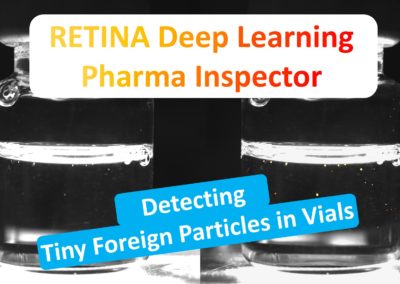

If you’re committed to ecology and environmental responsibility and seeking ways to reduce production waste, we have the perfect solution. Our advanced retrofit and optimization technologies are designed to increase throughput while minimizing waste, ensuring a more sustainable manufacturing process. Using cutting-edge AI-powered deep learning, we enable complex, high-speed visual quality inspections, helping industries achieve both precision and sustainability.

Let’s innovate together—discover how 3HLE can transform your food production lines efficiency while supporting a greener future.

We are here to help

Most of our customers get to know us in critical/crisis situations on their machines or in their businesses. After a successful collaboration with “3HLE”, all of them testimony positively “We were unfortunate on this project at the beginning but we are lucky to get to know 3HLE”. This is how we keep continue working together. SOme of our customers allow us to illustrate their applications on our website in the “Showcases” section.

Now the question is “What and How can we help?” We do support and provide the services below for B2B as well as B2C.

- Audit and Training on Industrial Vision and Factory Automation Applications.

- R&D for new applications solutions reducing risk, anticipate machine stops and provide a trend of the production.

- Retrofit production machines for better quality products and decrease the production waste/cost.

- Develop software for machine & sensors interaction, HMI, controls and dashboarding for a production yield overview.

- Create vision algorithms to provide human/operator a tool to help deciding the quality of products using artificial intelligence and deep learning.

“3HLE” is mainly offering Turn-Key solutions including Hardware, Integration of Software and Automation Processes dedicated to high speed automated Computer Vision Quality Control applications. For more Showcases, check out our Sucess Stories pages or check out our Products pages to learn more about our hardware and software solutions. We are working to build up more and more contents in those sections, please subscribe to our “3HLE” LinkedIn, FaceBook or Youtube chanels to get notified as soon as new contents will be available.

Clients

50+ Satisfied recurrent customers in 6 different sectors:

- Watch Manufactures & Industry (well-known Luxury and Prestigious Watch Manufactures)

- Food & Beverage (Coffee, Chocolate, Soft drinks, including mass-production coffee pods/capsules, etc…)

- Semi-Conductor Industry (Sensors, Modules, Packaging, Assembly, etc…).

- Medical devices.

- Logistics applications.

- Automotive parts industries.

Please fill in the section below to receive the selected PDF Datasheet by email

Applications

Improve Yield / Reduce Waste / Quality Inspections / Pick & Place / Track & Trace / Increase Performance & Throughput / Robust Software Design / Intuitive & User-Friendly Interface

A.I. Machine Vision check Packaging sealing integrity

A.I. Machine Vision check Packaging sealing integrity

How to detect scratches on glass and shiny metallic parts

Detection of scratches on glass and shiny watch parts

Comments are Closed