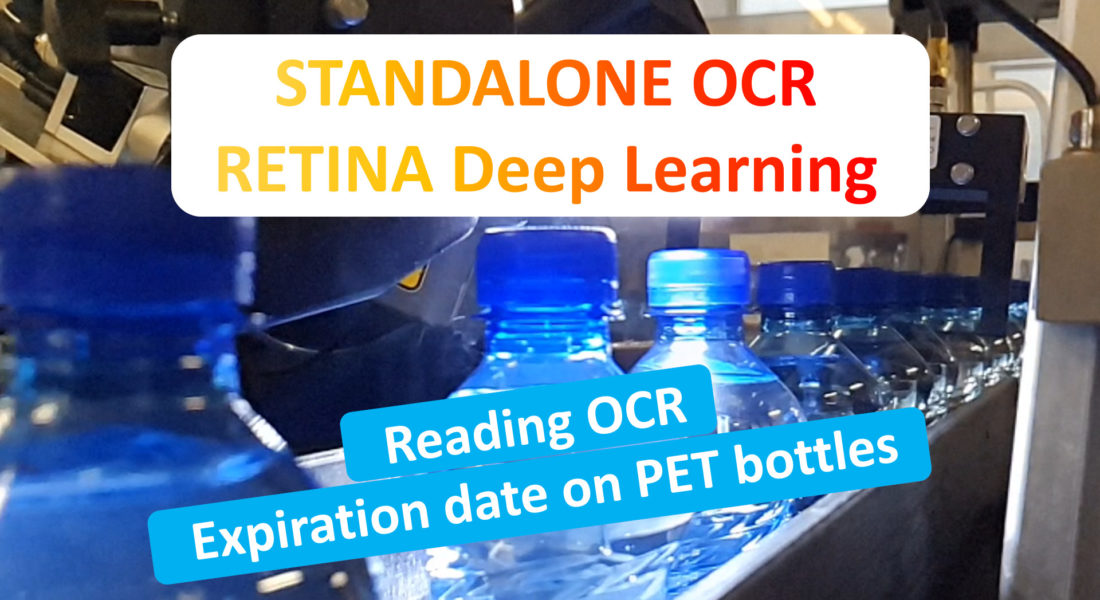

Standalone Deep Learning Retina-Olive reading Characters on PET Bottles Production Lines

Did you know that all “PET bottles” are marked with an expiration date? The printing quality depends on the production line speed, the used technology to mark bottle. So far, conventional vision software can read quite well when it comes to the same bottle color, the same speed and the same liquid contents. Deep learning technology allows manufacturers to reduce the cost of vision system maintenance and fine-tuning by training the software to adapt to the variation of different recipe (PET bottles color and its contents as well as characters distorsion or mis-engraved). Being able to read as good as human, manufacturers can reduce the amount of rejected bottles/waste that need to be processed and evacuated.

The reliable and high speed OCR reading tool is based on “Artificial Intelligence” Retina Olive deep learning OCR solutions.

We are able to read more than 50’000 parts/hour with a read rate of 99.99%. “3HLE” Automation et Robotique SA will be happy to warranty the best read rate out of your production line be it automatic or manual processes.

Check out the showcase demo video below for solving within minutes a typical food and beverage OCR application on PET transparent surfaces. This video show how we can read quickly a human-like OCR on curvy and transparent colored PET bottles surfaces.

The conventional OCR tools could reach 95% read rate on 1 type of liquid after many days fine-tuning and tricks to accept bad characters in the read string. Our Retina Olive OCR tool could reach easily 99.99% read rate within a few hours without any confusion.

“3HLE” is specialized in high speed automated Deep Learning OCR applications. If you are concerned of “Ecology and Environement” and would like to reduce final product waste by detecting defects or mis-printing at an earlier stage of the production, feel free to drop us an email or a phone call to discuss about improving or retrofitting your production lines to increase throughput and detect defects before it get higher added values using our cutting edge technologies.

You are welcome to challenge Retina Olive OCR deep learning algorithm with your application! We are ourselve surprised by its performance on very low resolution images and high noise backgrounds!!!

“3HLE” is active in Watches and Food Industries. If you are concerned of “Ecology and Environement” and would like to reduce production waste, feel free to contact us to discuss about improving or retrofitting your production lines to increase throughput and reduce waste using cutting edge technologies.

“3HLE” is mainly offering Turn-Key solutions including Hardware, Integration of Software and Automation Processes dedicated to high speed automated Computer Vision Quality Control applications. For more Showcases, check out our Sucess Stories pages or check out our Products pages to learn more about our hardware and software solutions. We are working to build up more and more contents in those sections, please subscribe to our “3HLE” LinkedIn, FaceBook or Youtube chanels to get notified as soon as new contents will be available.

Comments are Closed