How to set up a Complex Surface Flaw Detection within Minutes without being a Deep Learning Machine Vision Expert

Products packaging is more important than what we think. Even if the inner product is not damaged, people tend to choose the prettiest boxes because the exterior is reflecting how well a product has been handled and produced. Most of the time, people are judging the price of a product based on the external visual and feeling of the packaging. For example, people are not willing to pay original price for a luxury product in a broken/damaged package. The difference between a high end brand and a low cost brand is simply the probability to get a bad part when purchasing a product. Consumers are willing to pay more for a constant and known quality.

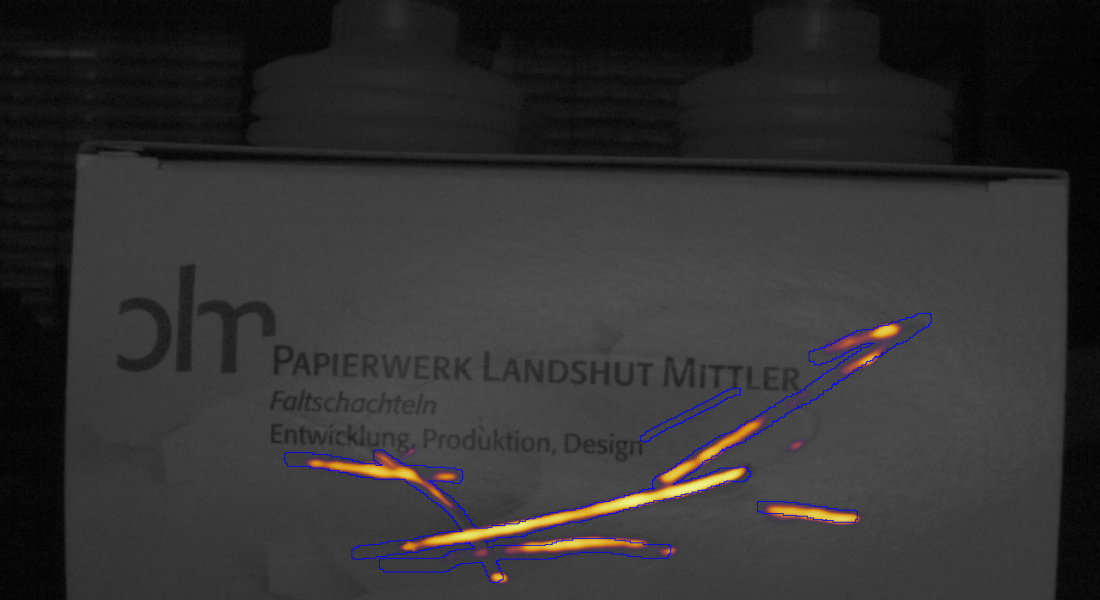

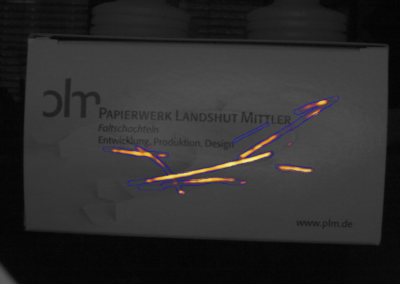

Many industries around the world rely on High Quality Swiss Standard for Luxury goods (perfumes, watches and production machines allowing to manufacture end products). The quality inspections are performed on critical steps of the production process to warranty the conformity of the contents as well as the external visual aspect. Traditional machine vision is performing well some of these tasks, but usually failed in detecting aesthetic aspect of the products like cracks, wrinkles, scratches, oil, glue and other materials on transparent parts (e.g. cracks/scratches on jewelery stones, oil or finger print on watch saphire or other parts, wrinkles on perfumes packaging, transparent glue on paper, etc…). This is where our Retina Deep learning machine vision software can help detecting tricky surface defects. And this can be performed directly on the edge of the production lines without transferring anything to the web.

The complex and high speed visual quality inspections are based on embedded “Artificial Intelligence” deep learning server/solutions. Images are processed directly on the edge of the machines. Our solutions is deployed on local IPC with GPU within the factory network. Manufacturers will be able to access production datas and images on the edge of their machines or through their internal network without the need to rely on a stable internet connection.

“3HLE” Automation et Robotique SA will be happy to perform feasibilities on your samples to showcase the power of RETINA. We will be glad to warranty the best quality out of your production line be it automatic or manual processes.

Check out the showcase demo video below (setup very quickly) for a complex surface inspection using a collaborative Universal Robot UR3E for a sorting task within minutes. This demo video show how we can setup quickly a human-like inspection on a challenging packaging surface.

“3HLE” is specialized in high speed automated Computer Vision Quality Inspection. If you are concerned of “Ecology and Environement” and would like to reduce final product waste by detecting defects at an earlier stage of the production, feel free to drop us an email or a phone call to discuss about improving or retrofitting your production lines to increase throughput and detect defects before it get high added values using cutting edge technologies.

“3HLE” is mainly offering Turn-Key solutions including Hardware, Integration of Software and Automation Processes dedicated to high speed automated quality control applications. For more Showcases, check out our Sucess Stories pages or check out our Products pages to learn more about our hardware and software solutions. We are working to build up more and more contents in those sections, please subscribe to our “3HLE” LinkedIn, FaceBook or Youtube chanels to get notified as soon as new contents will be available.

Please fill in the section below to receive the selected PDF Datasheet by email

Comments are Closed